Humankind’s most needed commodity, energy, is in infinite supply. It’s how we harness or extract it that’s the burning issue.

Humankind’s most needed commodity, energy, is in infinite supply. It’s how we harness or extract it that’s the burning issue.

The Port of Milford Haven is known as the energy capital of the UK. We were in the right place at the right time when the nation needed refineries and port infrastructure to receive and process first oil and then liquefied natural gas (LNG) hydrocarbons to heat its homes and to power its transport and industry. The Waterway’s sheltered depths and its location close to global shipping routes made it a critical nexus for UK PLC.

The same assets, along with the capabilities that 60 years of being an energy capital have nurtured, are now helping the Port and the region to secure a prominent position in the global race to decarbonise energy production. The Pembroke Dock Marine project, creating a world class centre for the development of marine energy, is underway. But there’s also a lot of excitement around hydrogen.

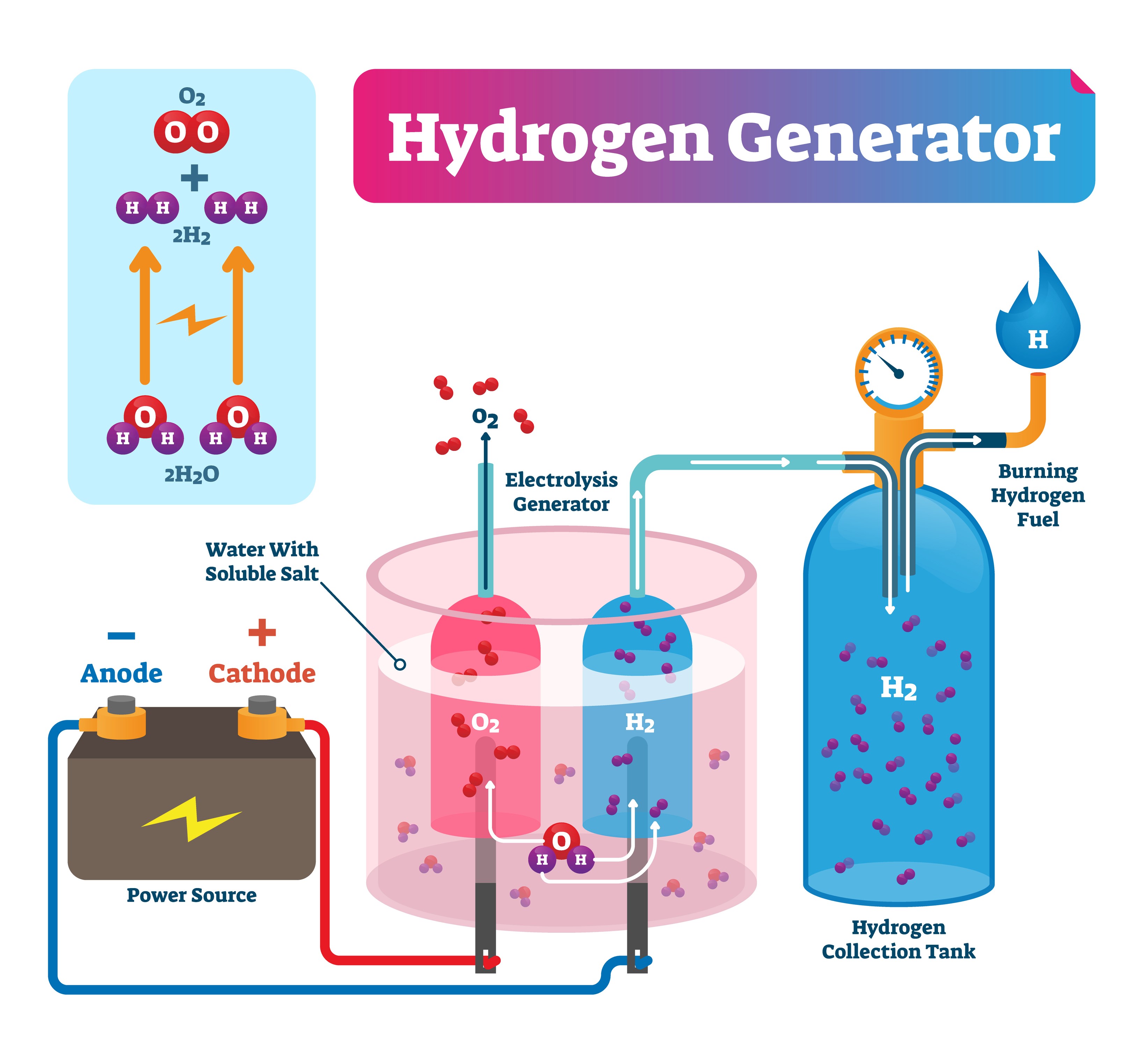

Hydrogen (H2) is the most abundant element in the universe but rarely travels alone. It teams up with Earth’s most ubiquitous element, oxygen (O), to make water (H2O). This pairing, without which there could be no life on Earth, can be unpicked relatively simply – although energy intensively - using electricity. Applying an electrical charge through positive and negative electrodes dipped in water quite literally decomposes it into bubbles of its two basic ingredients. Using this process, surplus electricity generated offshore could be diverted to make hydrogen, which can be stored.

“Pembrokeshire has an opportunity to play a vital national role in driving new green growth in floating offshore wind (FLOW), marine energy generation and hydrogen” explains Steve Edwards, Commercial Director.

“The addition of hydrogen is critical here, not least because our ability to make and store it when there’s spare electricity means renewable energy can be kept for when Mother Nature is otherwise unable to provide.”

Using fuel cell technology, we can reverse the electrolysis process and generate electricity, from the stored hydrogen’s repairing with oxygen, and the only by-product is water. This is how most hydrogen fuelled electric vehicles operate. This chemically elementary process could hold the key to helping us smooth the unavoidable peaks and troughs of renewable energy generation that relies on sun, wind, wave or tide.

“While there may be some debate about how hydrogen fits into our plans to reach Net Zero, and how we extract it, we believe it has a big part to play as we add more renewable sources to our energy mix” says Tim James, Head of Energy Development at the Port. “That’s why the Port and its partners in the Milford Haven: Energy Kingdom project are leading the way, as this coastal region offers the very best imaginable combination of assets – its pipelines, pylons, port and people - to make the most of hydrogen’s potential.”

MILFORD HAVEN: ENERGY KINGDOM

MH:EK is exploring the use of zero carbon hydrogen alongside renewable electricity to meet all of our future energy needs for buildings, power generation and fuelling transport. This collaborative project, led by Pembrokeshire County Council, explores what a decarbonised smart local energy system could look like for Milford Haven, Pembroke and Pembroke Dock.

“We’ve installed this pioneering hydrogen refilling station for fuel cell cars here at Milford Waterfront,” explains Tam Bardell, Energy Development Manager at the Port. “It’s a brilliant concept: an electrolyser that can use spare energy from our solar arrays to create, store and dispense hydrogen. We also have two RASA prototype cars from Welsh firm Riversimple here on trial, showcasing zero carbon transport as it could be.”

Watch the video of the Milford Haven: Energy Kingdom launch:

HYDROGEN BLUES

Towards 2050, if we are to switch our heating from gas (or oil where gas is not available) to electric, using heat pumps for example, we will have to ramp up green electricity production massively. The UK will need to triple its generation capacity to deal with the switch and to support the roll out of EV charging. We will also have to invest in power lines and home insulation and to upgrade the heating systems of millions of homes and offices.

The owner of Pembroke Power Station, RWE, has announced that, with its focus on decarbonising its business entirely by 2040, it will pursue opportunities in on and offshore renewables, looking into options for developing an electrolyser plant to supply local heavy energy users as well as using hydrogen within the plant. For the last, it will need a lot more hydrogen than could be produced through electrolysing so-called ‘green hydrogen’ from spare capacity on windy days. As Tim James explains, that demand could be met by ‘blue hydrogen’ as well.

“Hydrogen can also be produced by stripping it from natural gas (methane – CH4). But, when hydrogen is stripped from methane, what does the process leave you with? CO2, the very gas we are trying to eliminate from the energy formula!”

“We use the term ‘blue hydrogen’ to describe hydrogen stripped from methane, where the waste CO2 is then captured, shipped or piped away and stored in underground caverns, such as the voids created by extracting gas and oil deep under the sea floor,” says Tim. “RWE is part of a consortium seriously looking at this option and if it can be done cost effectively and efficiently, it will be a very neat solution.”

COLLABORATION

And if carbon capture and shipping is viable for South Wales, many others in the region stand to benefit. RWE is one of the partners of the South Wales Industrial Cluster (SWIC), which also includes energy-intensive businesses such as Valero, Tarmac and Tata Steel, SMEs including the Port of Milford Haven, and Pembrokeshire County Council. The collective SWIC collaboration on hydrogen use and carbon capture and storage may be crucial to Wales’ ambitious decarbonising targets.

Detractors believe any energy equation that has CO2 in it is the wrong way to go. However, it is possible that the timescales involved and the practical challenges of decarbonising the nation’s heat, transport and industrial complexes are going to be tough without blue hydrogen playing a role.

Be it green or blue, this simple and abundant element will have a lot to offer us over the next few decades. Producing it more cheaply and learning how to make it a part of our energy mix as soon as possible can only bring down the cost of going green. The Port of Milford Haven has committed to invest over £50m in the next five years to support and grow the energy cluster for a decarbonised future. With similar commitment coming from other members of the South Wales Industrial Cluster, we can not only make our contribution to Wales’ targets, but also make the region a world leader in zero carbon technology.

Livelihoods, as well as lives, depend on it.